top of page

DC3

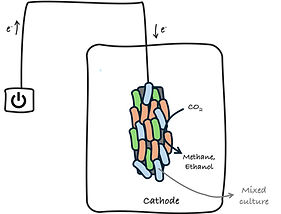

Process intensification for bioelectro CO2 recycling into carbon-neutral products

Widget Didn’t Load

Check your internet and refresh this page.

If that doesn’t work, contact us.

THE SUPERVISORS

Sebastià Puig

University de Girona

Deepak Pant

VITO

THE CANDIDATE

Jose Daniel Izquierdo Moreno

Passionate about advancing microbial electrochemical technologies for sustainable CO₂ conversion into value-added products

bottom of page